Honda Civic Service Manual: Steering Tie-Rod End Ball Joint Boot Replacement

5111A8 LEFT

5111A9 RIGHT

5111B0 BOTH

|

|

1.

|

Raise the vehicle on a lift, and make sure it is securely supported.

|

|

|

|

|

1.

|

Remove the front wheel.

|

|

|

|

Always use a ball joint remover to disconnect a ball joint. Do not strike

the housing or any other part of the ball joint connection to disconnect

it.

|

1.

|

Install a hex nut (A) or the ball joint thread protector.

|

|

NOTE: When using a hex nut, make sure the nut is flush with the

ball joint pin end to prevent damage to the threaded end of the

ball joint pin.

|

|

|

ov ov

|

|

2.

|

Apply grease to the ball joint remover on the areas shown (A).

|

|

|

wmae-sldaidz wmae-sldaidz

|

|

3.

|

Install the ball joint remover as shown.

|

|

NOTE:

|

|

|

Fasten the safety chain (A) securely to a suspension

arm or the subframe (B).

|

|

|

|

Making sure not to damage the ball joint boot.

|

|

|

|

4.

|

Tighten the pressure bolt until the ball joint pin pops loose

from the ball joint connecting hole.

|

|

NOTE: Do not use pneumatic or electric tools on the pressure

bolt.

|

|

5.

|

Remove the ball joint remover.

|

|

6.

|

Remove the hex nut or the ball joint thread protector.

|

|

7.

|

Pull the ball joint out of the ball joint connecting hole.

|

|

| 4. |

Tie-Rod End Ball Joint - Disconnection |

|

|

|

1.

|

Remove the cotter pin (A).

|

|

3.

|

Disconnect the tie-rod end ball joint.

|

|

| 5. |

Tie-Rod End Ball Joint Boot |

|

|

|

1.

|

Remove the ball joint boot (A) from the tie-rod end, and wipe

the old grease off the ball pin.

|

|

| 1. |

Tie-Rod End Ball Joint Boot |

|

|

|

1.

|

Pack the lower area of the ball pin (A) with fresh multipurpose

grease.

|

|

2.

|

Pack the interior of the new ball joint boot (B) and the lip

(C) with fresh multipurpose grease.

|

|

Note these items when installing new grease:

|

|

|

Keep grease off the boot mounting area (D) and

the tapered section (E) of the ball pin.

|

|

|

|

Do not allow dust, dirt, or other foreign materials

to enter the boot.

|

|

|

|

|

o1vags2xuiuu o1vags2xuiuu

|

|

3.

|

Install the ball joint boot (A) using the bearing driver attachment.

|

|

4.

|

The ball joint boot must not have a gap at the ball joint boot

installation sections (B).

|

|

5.

|

After installing the ball joint boot, check the ball pin tapered

section for grease contamination.

|

|

6.

|

Wipe the ball pin tapered section if necessary.

|

|

| 2. |

Tie-Rod End Ball Joint - Reconnection |

|

i2mmonum i2mmonum

|

|

1.

|

Connect the tie-rod end ball joint.

|

|

3.

|

Install the cotter pin (B) as shown.

|

|

|

mmmln-mnomm mmmln-mnomm

|

|

1.

|

Install the front wheel.

|

|

NOTE: Before installing the wheel, clean the mating surfaces

between the brake disc and the inside of the wheel.

|

|

|

|

For proper inspection and adjustment of the wheel alignment,

do these checks:

|

|

1.

|

Release the parking brake to avoid an incorrect measurement.

|

|

2.

|

Make sure the suspension is not modified.

|

|

3.

|

Make sure the fuel tank is full, and that the tire repair kit,

the spare tire, the jack, and the tools are in place on the vehicle.

|

|

4.

|

Check the tire size and tire pressure according to tire information.

|

|

|

|

Use commercially available computerized four wheel alignment

equipment to measure wheel alignment (caster, camber, toe, and turning

angle). Follow the equipment manufacturer's instructions.

|

|

1.

|

Check the caster angle.

|

|

USA and Canada models

|

Caster angle:

|

| |

Except Si:

|

5 ° 19 ’±30 ’

|

| |

Si (Without 18 inch wheel):

|

5 ° 22 ’±30 ’

|

| |

Si (With 18 inch wheel):

|

5 ° 15 ’±30 ’

|

|

|

|

|

Mexico models

|

Caster angle:

|

| |

Without 18 inch wheel:

|

5 ° 10 ’±30 ’

|

| |

With 18 inch wheel:

|

5 ° 6 ’±30 ’

|

|

|

|

|

|

If the measurement is within specifications,

measure the front camber angle.

|

|

|

|

If the measurement is not within specifications,

check for bent or damaged suspension components.

|

|

|

|

|

|

Use commercially available computerized four wheel alignment

equipment to measure wheel alignment (caster, camber, toe, and turning

angle). Follow the equipment manufacturer's instructions.

|

|

1.

|

Check the camber angle.

|

|

USA and Canada models

|

Camber angle:

|

| |

Except Si:

|

| |

|

Front:

|

0 ° 00 ’±30 ’

|

| |

|

Rear:

|

-0 ° 45 ’±45 ’

|

| |

Si (Without 18 inch wheel):

|

| |

|

Front:

|

-0 ° 04 ’±30 ’

|

| |

|

Rear:

|

-0 ° 52 ’±45 ’

|

| |

Si (With 18 inch wheel):

|

| |

|

Front:

|

-0 ° 18 ’±30 ’

|

| |

|

Rear:

|

-0 ° 45 ’±45 ’

|

|

(Maximum difference between the front right and

left side: 0 ° 45 ’)

|

|

|

|

|

Mexico models

|

Camber angle:

|

| |

Front:

|

0 ° 20 ’±30 ’

|

| |

Rear:

|

-0 ° 22 ’±45 ’

|

|

(Maximum difference between the front right and

left side: 0 ° 45 ’)

|

|

|

|

|

|

If the measurement is within specification, measure

the toe-in.

|

|

|

|

If the measurement for the front camber is not

within the specification, go to front camber adjustment.

|

|

|

|

If the measurement for the rear camber is not

within the specification, check for bent or damaged

suspension components.

|

|

|

|

| 7. |

Front Toe - Inspection |

|

|

Use commercially available computerized four wheel alignment

equipment to measure wheel alignment (caster, camber, toe, and turning

angle). Follow the equipment manufacturer's instructions.

|

|

1.

|

Set the steering column to the middle tilt position and telescopic

positions.

|

|

2.

|

Center the steering wheel spokes, and install a steering wheel

holder tool.

|

|

3.

|

Check the toe with the wheels pointed straight ahead.

|

|

Front toe-in: 0±2 mm (0±0.08 in)

|

|

|

If adjustment is required, go to the front toe

adjustment.

|

|

|

|

If no adjustment is required, remove the alignment

equipment.

|

|

|

|

| 8. |

Turning Angle - Inspection |

|

|

|

Use commercially available computerized four wheel alignment

equipment to measure wheel alignment (caster, camber, toe, and turning

angle). Follow the equipment manufacturer's instructions.

|

|

1.

|

Turn the wheel right and left while applying the brake, and measure

the turning angle of both wheels.

|

|

USA and Canada models

|

Turning angle:

|

| |

Except Si:

|

| |

|

Inward:

|

38 ° 30 ’±2 °

|

| |

|

Outward (reference):

|

30 ° 47 ’±1 °

|

| |

Si (Without 18 inch wheel):

|

| |

|

Inward:

|

38 ° 22 ’±2 °

|

| |

|

Outward (reference):

|

30 ° 41 ’±1 °

|

| |

Si (With 18 inch wheel):

|

| |

|

Inward:

|

36 ° 33 ’±2 °

|

| |

|

Outward (reference):

|

29 ° 53 ’±1 °

|

|

|

|

|

Mexico models

|

Turning angle:

|

| |

Without 18 inch wheel:

|

| |

|

Inward:

|

39 ° 12 ’±2 °

|

| |

|

Outward (reference):

|

31 ° 14 ’±1 °

|

| |

With 18 inch wheel:

|

| |

|

Inward:

|

36 ° 58 ’±2 °

|

| |

|

Outward (reference):

|

30 ° 16 ’±1 °

|

|

|

|

|

2.

|

If the measurement is not within the specifications, even up

both sides of the tie-rod threaded section length while adjusting

the front toe.

|

|

3.

|

If it is correct, but the turning angle is not within the specifications,

check for bent or damaged suspension components.

|

|

|

|

|

1.

|

Turn the wheel right and left while applying the brake, and measure

the turning angle of both wheels.

|

|

USA and Canada models

|

Turning angle:

|

| |

Except Si:

|

| |

|

Inward:

|

38 ° 43 ’±2 °

|

| |

|

Outward (reference):

|

30 ° 55 ’±1 °

|

| |

Si:

|

| |

|

Inward:

|

38 ° 36 ’±2 °

|

| |

|

Outward (reference):

|

30 ° 49 ’±1 °

|

|

|

|

|

Mexico models

|

Turning angle:

|

| |

Inward:

|

39 ° 15 ’±2 °

|

| |

Outward (reference):

|

31 ° 21 ’±1 °

|

|

|

|

|

2.

|

If the measurement is not within the specifications, even up

both sides of the tie-rod threaded section length while adjusting

the front toe.

|

|

3.

|

If it is correct, but the turning angle is not within the specifications,

check for bent or damaged suspension components.

|

|

|

|

|

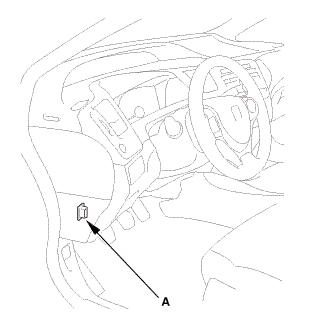

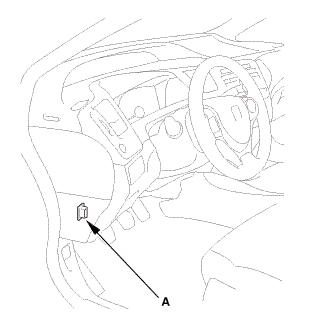

1.

|

Connect the HDS to the data link connector (DLC) (A) located

under the driver's side of the dashboard.

|

|

2.

|

Turn the ignition switch to ON (II).

|

|

3.

|

Make sure the HDS communicates with the vehicle. If it does not

communicate, go to the DLC circuit troubleshooting.

|

|

| 10. |

VSA Sensor Neutral Position - Memorization |

|

|

1.

|

Park the vehicle on a flat and level surface, with the steering

wheel in the straight ahead position.

|

|

2.

|

Select VSA ADJUSTMENT, then select ALL SENSORS with the HDS,

and follow the screen prompts.

|

|

NOTE: See the HDS Help menu for specific instructions.

|

|

| 11. |

Steering Angle Sensor Neutral Position - Clear |

|

|

1.

|

Select EPS ADJUSTMENT, then select EPS STEERING ANGLE SENSOR

VALUE CLEAR and follow the screen prompts on the HDS.

|

|

NOTE: See the HDS Help menu for specific instructions.

|

|

5131B1

1.

Vehicle Lift

1.

Raise the vehicle on a lift, and make sure it is securely supported.

...

SRS components are located in this area. Review the SRS component locations,

and the precautions and procedures before doing repairs or service.

1.

Battery T ...

Steering Rack Guide Removal and Installation

Steering Rack Guide Removal and Installation Steering Column Removal and Installation

Steering Column Removal and Installation

ov

ov wmae-sldaidz

wmae-sldaidz

o1vags2xuiuu

o1vags2xuiuu i2mmonum

i2mmonum mmmln-mnomm

mmmln-mnomm