Honda Civic Service Manual: EPS Motor Removal and Installation

511102

|

NOTE: Do not allow dust, dirt, or other foreign materials to enter the steering gearbox. |

| 1. | Vehicle Lift |

|

| 2. | Front Wheel |

|

|

|

| 3. | Steering Joint Cover |

|

|

|

| 4. | Steering Column Lower Slide Shaft - Hold |

|

|

|

| 5. | Steering Wheel Hold |

|

|

|

| 6. | Steering Joint Bolt - Loosen |

|

|

|

| 7. | Steering Joint - Disconnection |

|

|

|

||||||||||||||||||||

| 8. | Ball Joint - Removal |

|

|

Always use a ball joint remover to disconnect a ball joint. Do not strike the housing or any other part of the ball joint connection to disconnect it.

|

||||||

|

|

|

|

|

|

||||||||||||||||||||||||||||||||

| 9. | Tie-Rod End Ball Joint - Disconnection, Both Side |

|

|

|

||||||||||||

| 10. | Engine Undercover |

|

|

|

| 11. | Splash Shield |

|

1. |

Remove the splash shield (A). |

| 12. | Power Steering Gearbox Peripheral Assembly |

|

|

|

|

Driver’s side

Passenger’s side

|

|

| 13. | EPS Motor |

|

|

|

|

NOTE: Do not allow dust, dirt, or other foreign materials to enter the steering gearbox. |

| 1. | EPS Motor |

|

|

|

| 2. | Power Steering Gearbox Peripheral Assembly |

|

|

|

|

|

|

|

|

|

|

|

|

| 3. | Splash Shield |

|

1. |

Install the splash shield (A). |

| 4. | Engine Undercover |

|

|

|

| 5. | Tie-Rod End Ball Joint - Connection, Both Side |

|

|

|

|||||||||||||||

| 6. | Steering Column Lower Slide Shaft - Release |

|

|

|

| 7. | Steering Wheel Release |

|

|

|

| 8. | Steering Joint - Reconnection |

|

|

|

||||||||||||||||||||

|

|

|

| 9. | Steering Joint Bolt - Tighten |

|

|

|

| 10. | Steering Joint Cover |

|

|

|

| 11. | Front Wheel |

|

|

|

||||||

| 12. | Steering Gearbox - After Install Symptom Check |

|

|||||||||||||||||

| 13. | Steering After Install - Check |

|

|||||||||||||||||||

| 14. | Pre-Alignment Checks |

|

| 15. | Caster - Inspection |

|

|||||||||||||||||||||||||||||||||||||||||||||||

| 16. | Camber - Inspection |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17. | Front Toe - Inspection |

|

|||||||||||||||||||||||||

| 18. | Turning Angle - Inspection |

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19. | HDS DLC - Connection |

|

|

|

| 20. | EPS Torque Sensor Neutral Position - Memorizing |

|

||||||||||||||||

| 21. | VSA Sensor Neutral Position - Memorization |

|

||||||||||

| 22. | Steering Angle Sensor Neutral Position - Clear |

|

|||||||

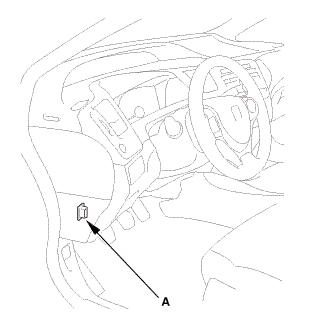

EPS Control Unit Removal and Installation

EPS Control Unit Removal and Installation

513130

Removal

1.

Front Door Sill Trim - 2-Door

1.

Remove the front door sill trim (A).

...

Power Steering Assist Check

Power Steering Assist Check

Check

1.

Power Steering Assist Check

NOTE: This test should be done with original equipment tires and wheels

at the correct tire pressure.

...

See also:

Honda Civic Service Manual. Passenger's Dashboard Trim Panel Removal and Installation (Without Navigation)

8411K3

1.

Driver's Dashboard Lower Cover

1.

Remove the driver's dashboard lower cover (A).

2.

Dashboard Subdisplay Visor

...

ov

ov wmae-sldaidz

wmae-sldaidz n7aaf-sdaainnmm

n7aaf-sdaainnmm

ixusmm

ixusmm

m,iminmm

m,iminmm mmm:im

mmm:im

mm:.o21

mm:.o21

mmmln-mnomm

mmmln-mnomm