Honda Civic Service Manual: Engine Oil/Air Separator Removal and Installation (R18Z1)

1111M5

Removal

|

|

|

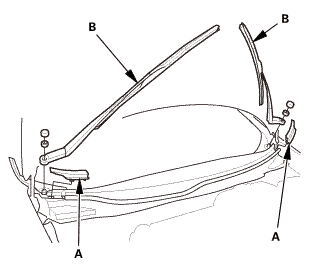

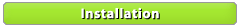

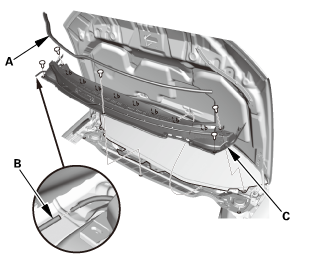

NOTE: Set the wiper arms to the auto-stop position before removal.

|

|

1.

|

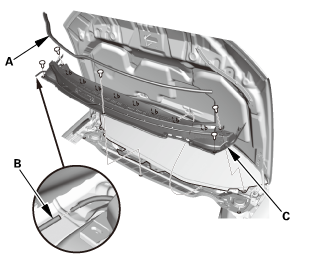

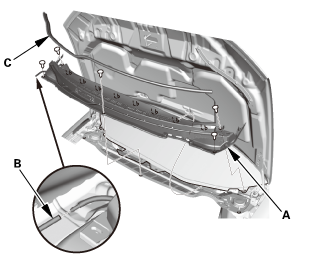

Remove the cowl top wiper covers (A).

|

|

2.

|

Remove the wiper arms (B).

|

|

|

|

|

1.

|

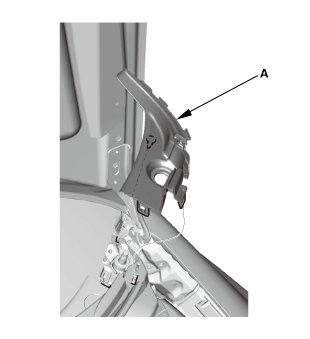

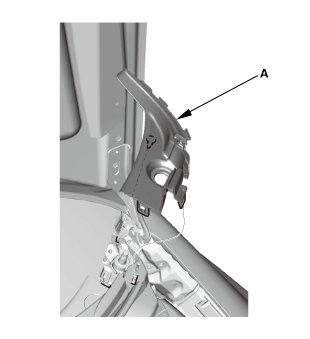

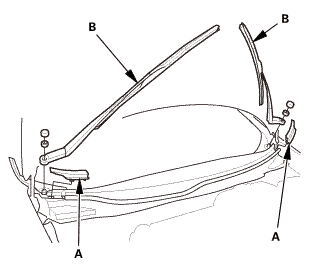

Remove the side cowl cover (A).

|

|

2.

|

The left side is shown; repeat on the right side.

|

|

|

|

|

1.

|

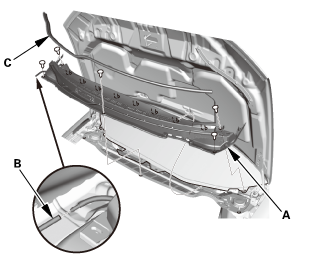

Remove the center cowl cover (A).

|

|

2.

|

Disconnect the windshield washer tube (B).

|

|

3.

|

If necessary, remove the hood rear seal (C).

|

|

|

|

|

1.

|

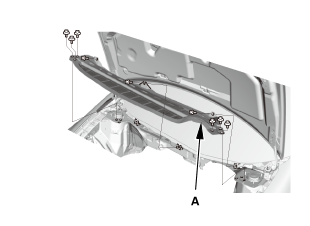

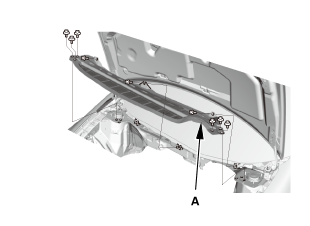

Remove the under cowl panel (A).

|

|

|

|

1.

|

Remove the fuel fill cap to relieve the pressure in the fuel

tank.

|

|

|

|

|

NOTE: For specific operations, refer to the user's manual that

came with the Honda Diagnostic System (HDS). Make sure the HDS is

loaded with the latest software.

|

|

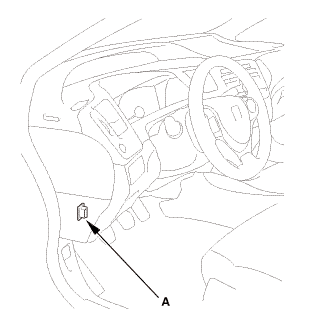

1.

|

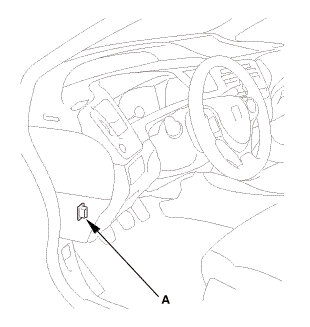

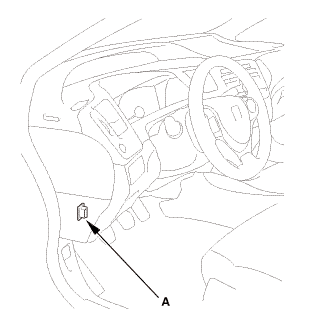

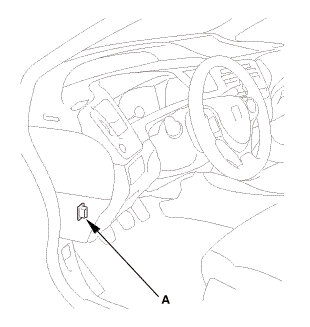

Connect the HDS to the data link connector (DLC) (A) located

under the driver's side of the dashboard.

|

|

2.

|

Turn the ignition switch to ON (II).

|

|

3.

|

Make sure the HDS communicates with the vehicle. If it does not

communicate, go to the DLC circuit troubleshooting.

|

|

|

|

1.

|

Turn the ignition switch to ON (II).

|

|

2.

|

From the INSPECTION MENU of the HDS, select Fuel Pump OFF, then

start the engine, and let it idle until it stalls.

|

|

NOTE:

|

|

|

Do not allow the engine to idle above 1,000 rpm

or the ECM/PCM will continue to operate the fuel

pump.

|

|

|

|

Pending or Confirmed DTC may be set during this

procedure. Check for DTCs, and clear them as needed.

|

|

|

|

3.

|

Turn the ignition switch to LOCK (0).

|

|

| 8. |

Battery Terminal - Disconnection |

|

|

|

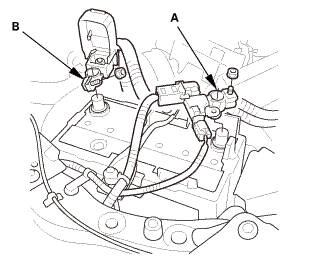

1.

|

Make sure the ignition switch is in LOCK (0).

|

|

2.

|

Disconnect and isolate the negative cable and battery sensor

(A) from the battery.

|

|

NOTE: Always disconnect the negative side first.

|

|

3.

|

Disconnect the positive cable (B) from the battery.

|

|

| 9. |

Fuel Pressure - Relieving |

|

|

|

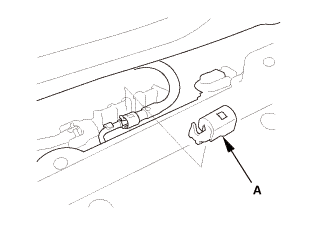

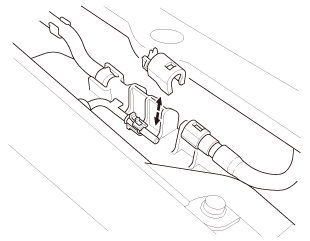

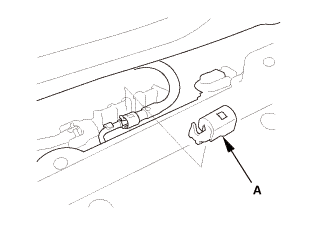

1.

|

Remove the quick-connect fitting cover (A).

|

|

2.

|

Check the fuel quick-connect fitting for dirt, and clean it if

needed.

|

|

|

|

|

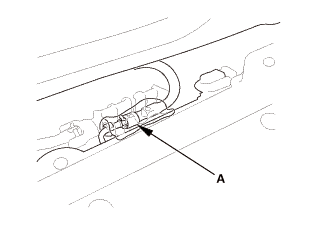

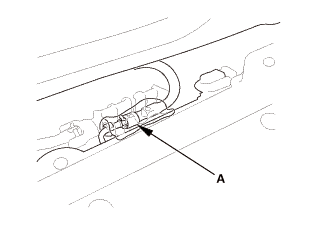

3.

|

Place a rag or shop towel over the quick-connect fitting (A).

|

|

|

|

|

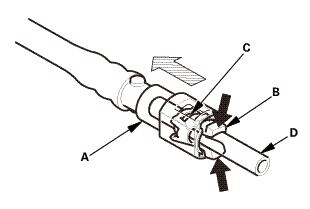

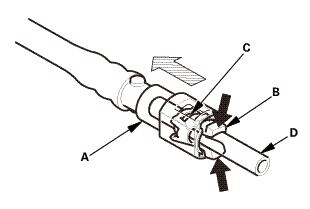

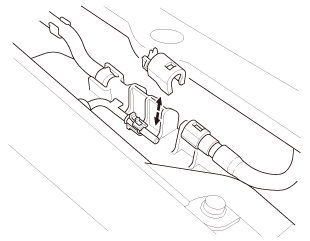

4.

|

Disconnect the quick-connect fitting: Hold the connector (A)

with one hand, and squeeze the retainer tabs (B) with the other

hand to release them from the locking tabs (C). Pull the connector

off.

|

|

NOTE:

|

|

|

Be careful not to damage the line (D) or other

parts.

|

|

|

|

Do not use tools.

|

|

|

|

If the connector does not move, keep the retainer

tabs pressed down, and alternately pull and push

the connector until it comes off easily.

|

|

|

|

Do not remove the retainer from the line; once

removed, the retainer must be replaced with a new

one.

|

|

|

|

|

|

|

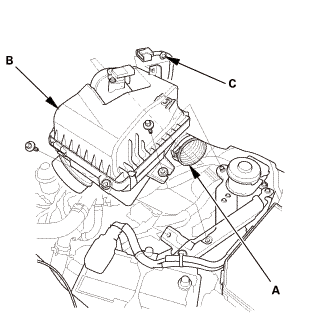

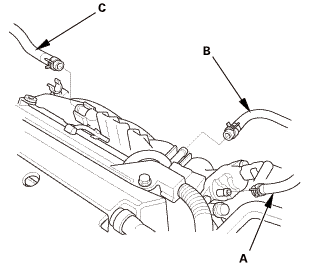

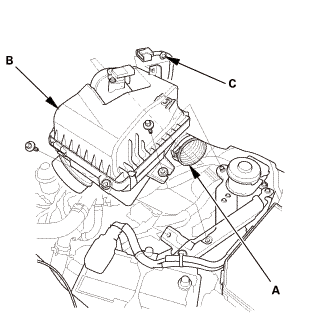

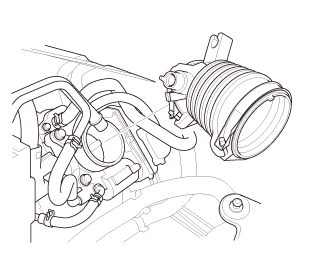

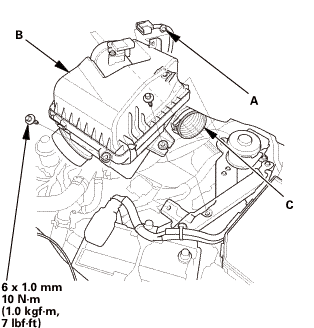

1.

|

Disconnect the intake air duct (A).

|

|

2.

|

Remove the air cleaner (B).

|

|

3.

|

Remove the harness clamp (C).

|

|

|

|

|

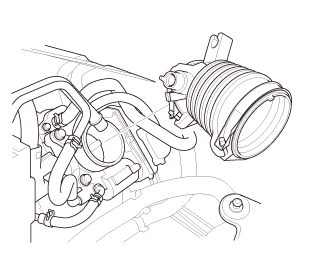

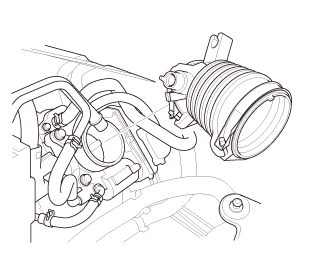

1.

|

Remove the intake air duct.

|

|

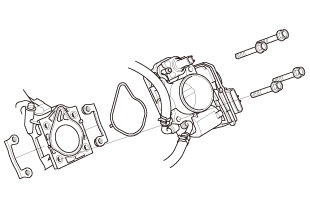

| 12. |

Throttle Body - Removal |

|

|

|

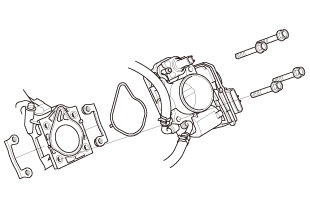

1.

|

Remove the throttle body without disconnecting the hoses.

|

|

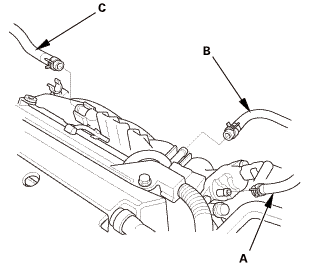

| 13. |

Intake Manifold Assembly |

|

|

|

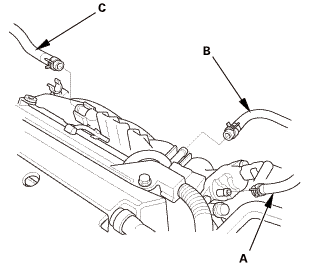

1.

|

Disconnect the EVAP canister hose (A), the brake booster vacuum

hose (B), and the PCV hose (C).

|

|

|

|

|

2.

|

Remove the heater hose clamp bracket.

|

|

|

|

|

3.

|

Remove the intake manifold bracket.

|

|

|

|

|

4.

|

Disconnect the connectors (A).

|

|

5.

|

Remove the harness clamps.

|

|

|

|

|

6.

|

Remove the intake manifold assembly.

|

|

|

|

|

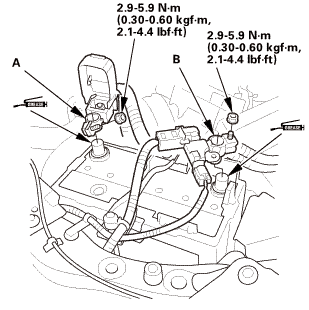

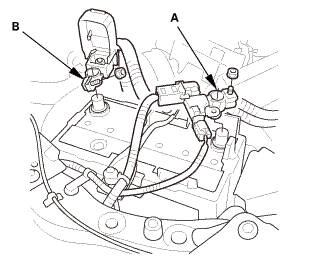

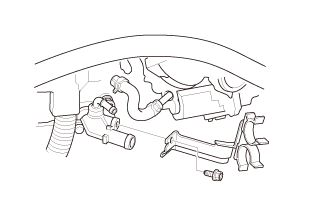

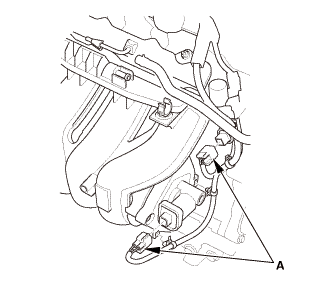

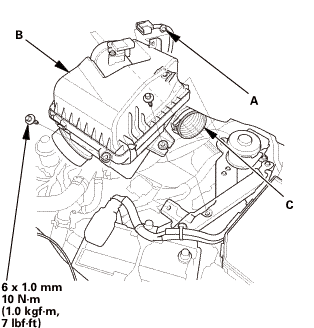

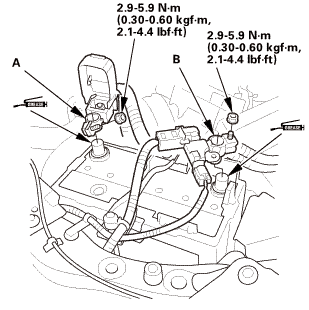

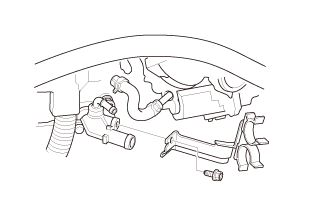

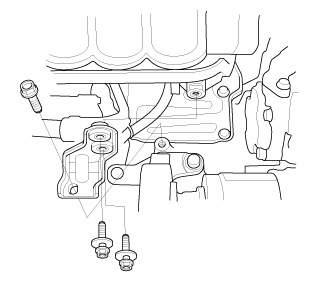

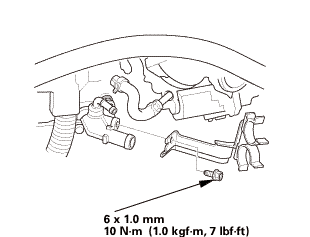

1.

|

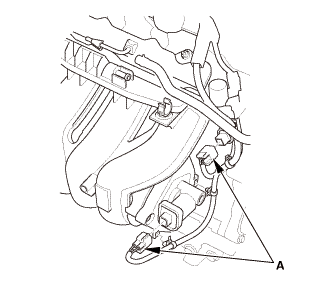

Remove the harness clamp (A) and the oil/air separator (B).

|

|

Installation

|

|

|

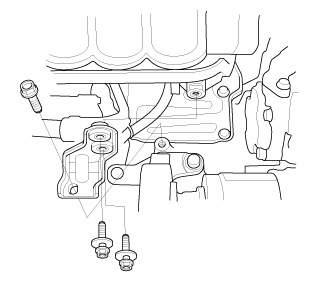

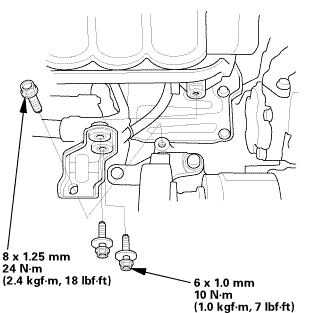

1.

|

Clean and dry the oil/air separator mating surfaces, the bolts,

and the bolt holes.

|

|

2.

|

Apply liquid gasket (P/N 08718-0004 or 08718-0009) to the engine

block mating surface of the oil/air separator and to the inner threads

of the bolt holes. Install the component within 5 minutes of applying

the liquid gasket.

|

|

NOTE:

|

|

|

Apply a 2.5 mm (0.098 in) diameter bead of liquid

gasket along the broken line (A).

|

|

|

|

If too much time has passed after applying the

liquid gasket, remove the old liquid gasket and

residue, then reapply new liquid gasket.

|

|

|

|

|

mm12 mm12

|

|

3.

|

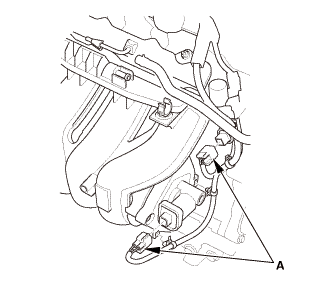

Install the oil/air separator (A).

|

|

NOTE:

|

|

|

Wait at least 30 minutes before filling the engine

with oil.

|

|

|

|

Do not run the engine for at least 3 hours after

installing the oil pump.

|

|

|

|

4.

|

Install the harness clamp (B).

|

|

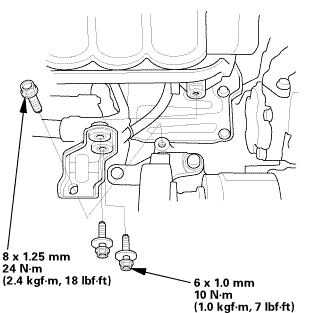

| 2. |

Intake Manifold Assembly |

|

mm mm

|

|

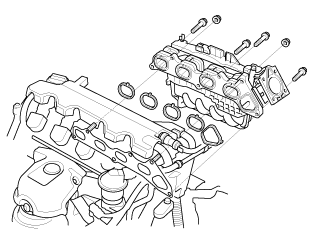

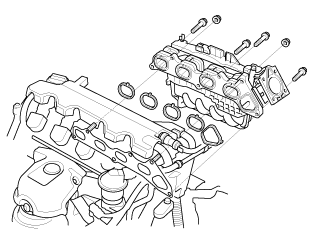

1.

|

Install the intake manifold assembly (A) with new gaskets (B).

|

|

2.

|

Tighten the bolts/nuts in a crisscross pattern in three steps,

beginning with the inner bolt.

|

|

|

|

|

3.

|

Install the connectors (A).

|

|

4.

|

Connect the harness clamps.

|

|

|

|

|

5.

|

Install the intake manifold bracket.

|

|

|

|

|

6.

|

Install the heater hose clamp bracket.

|

|

|

|

|

7.

|

Connect the EVAP canister hose (A), the brake booster vacuum

hose (B), and the PCV hose (C).

|

|

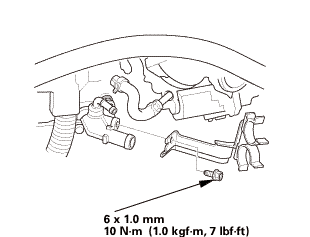

| 3. |

Throttle Body - Installation |

|

mm mm

|

|

1.

|

Install the throttle body (A) with new O-ring (B).

|

|

|

|

|

1.

|

Install the intake air duct.

|

|

|

|

|

1.

|

Install the harness clamp (A).

|

|

2.

|

Install the air cleaner (B).

|

|

3.

|

Connect the intake air duct (C).

|

|

| 6. |

Injector Base Fuel Feed Hose - Reconnection |

|

|

|

1.

|

Connect the fuel feed hose.

|

|

|

22mm)2222 22mm)2222

|

|

1.

|

Install the under cowl panel (A).

|

|

|

|

|

1.

|

If necessary, install the hood rear seal (A).

|

|

2.

|

Connect the windshield washer tube (B).

|

|

3.

|

Install the center cowl cover (C).

|

|

|

|

|

1.

|

Install the side cowl cover (A).

|

|

2.

|

The left side is shown; repeat on the right side.

|

|

|

1.122 1.122

|

|

NOTE: Set the wiper arms to the auto-stop position before installation.

|

|

1.

|

Install the wiper arms (A).

|

|

2.

|

Install the cowl top wiper covers (B).

|

|

|

|

1.

|

Install the fuel fill cap.

|

|

| 12. |

Battery Terminal - Reconnection |

|

|

|

NOTE: If the battery performs abnormally, test the battery.

|

|

1.

|

Clean the battery terminals.

|

|

2.

|

Connect the positive cable (A) to the battery.

|

|

NOTE: Always connect the positive side first.

|

|

3.

|

Connect the negative cable and battery sensor (B) to the battery.

|

|

4.

|

Apply multipurpose grease to the terminals to prevent corrosion.

|

|

|

|

|

1.

|

Connect the HDS to the data link connector (DLC) (A) located

under the driver's side of the dashboard.

|

|

2.

|

Turn the ignition switch to ON (II).

|

|

3.

|

Make sure the HDS communicates with the vehicle. If it does not

communicate, go to the DLC circuit troubleshooting.

|

|

|

|

1.

|

From the INSPECTION MENU of the HDS, select Fuel Pump ON.

|

|

NOTE: Pending or Confirmed DTC may be set during this procedure.

Check for DTCs, and clear them as needed.

|

|

2.

|

Turn the ignition switch to LOCK (0).

|

|

|

|

1.

|

Turn the ignition switch to ON (II) (but do not operate the starter

motor). The fuel pump runs for about 2 seconds, and fuel pressure

rises. Repeat this two or three times, then make sure there are

no fuel leaks.

|

|

| 16. |

Tubes, Hoses, and Connectors After Installation Check |

|

|

1.

|

After installation, check that all tubes, hoses, and connectors

are installed correctly.

|

|

1.

Warm Up The Engine

1.

Warm up the engine.

2.

Vehicle Lift

...

View

1.

Oil Pump Exploded View

Exploded View

mm27allon.pumpnowel......-m(1.2holder/bysoninbore

Disassembly

NOTE: Refer to the Exploded View ...

See also:

Honda Civic Owners Manual. About Your Audio System

The audio system features AM/FM radio and SiriusXM’ Radio service*. It can

also

play USB flash drives, and iPod, iPhone and Bluetooth’ devices.

You can operate the audio system from the buttons and switches on the panel, the

remote controls on the steering wheel, or the icons on the touch ...

Engine Oil Replacement

Engine Oil Replacement Engine Oil Pump Overhaul (K24Z7)

Engine Oil Pump Overhaul (K24Z7)

mm12

mm12 mm

mm

mm

mm

22mm)2222

22mm)2222

1.122

1.122