Honda Civic Service Manual: Cylinder Bore Honing (R18A9)

Removal

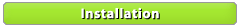

| 1. | Intake Manifold and Throttle Body Assembly (Natural Gas Model) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2. | Engine Wire Harness |

|

|

|

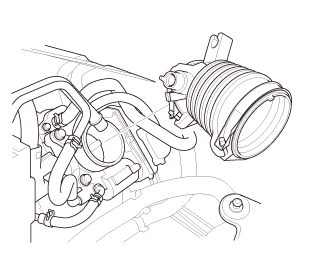

| 3. | Automatic Transmission Assembly (A/T) |

|

|

|

| 4. | Drive Plate Assembly |

|

|

|

| 5. | A/F Sensor (Sensor 1) |

|

|

|

| 6. | Exhaust Chamber Cover (Natural Gas Model) |

|

|

|

| 7. | Catalytic Converter (Natural Gas Model) |

|

|

|

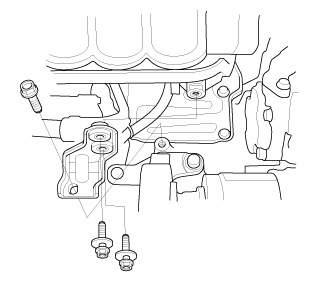

| 8. | Thermostat Housing (Natural Gas Model) |

|

|

|

| 9. | Alternator |

|

|

|

| 10. | Lower Torque Rod Bracket (A/T) |

|

|

|

| 11. | Intermediate Shaft Assembly |

|

|

|

|

|

|

||||||

| 12. | A/C Compressor Bracket |

|

|

|

| 13. | Water Pump Pulley |

|

|

|

| 14. | Auto Tensioner Assembly |

|

|

|

| 15. | Cylinder Head Cover and/or Packing |

|

|

|

|

|

|

| 16. | Check The No.1 Piston at Top Dead Center (With Cam Chain Case/Oil Pump) |

|

|

|

| 17. | Crankshaft Pulley |

|

|

|

| 18. | Engine Oil Pump Assembly |

|

|

|

|

|

|

| 19. | Cam Chain Auto-Tensioner |

|

|

|

||||||||||||

|

|

|

|

|

|

||||||||||||

|

|

|

| 20. | Cam Chain |

|

|

|

| 21. | Cylinder Head Assembly |

|

|

|

| 22. | Oil Pan Assembly |

|

|

|

|

|

|

| 23. | Engine Oil Strainer |

|

|

|

| 24. | Engine Baffle Plate |

|

|

|

| 25. | Connecting Rod Cap and The Bearing Half |

|

|

|

| 26. | Cylinder Lower Block Assembly |

|

|

|

|

|

|

|

|

|

|

|

|

| 27. | Crankshaft |

|

|

|

| 28. | Crankshaft Oil Seal, Transmission Side |

|

|

|

| 29. | Piston/Connecting Rod Assembly |

|

|

|

|

|

|

||||||||||||

| 30. | Engine Oil Jet |

|

|

|

Honing

Honing

| 1. | Cylinder Bore Honing |

|

1. |

Hone the cylinder bores with honing oil and a fine (400 grit) stone. |

|||||||||

|

||||||||||

|

NOTE: |

||||||||||

|

||||||||||

|

2. |

When honing is complete, thoroughly clean the engine block of all metal particles. Wash the cylinder bores with hot soapy water, then dry and oil them immediately to prevent rusting. |

|

|

NOTE: Never use solvent, it will only redistribute the grit on the cylinder walls. |

||

|

3. |

If scoring or scratches are still present in the cylinder bores after to the service limit, rebore the engine block. Some light vertical scoring and scratching is acceptable if it is not deep enough to catch your fingernail, and does not run the full length of the bore. |

Installation

| 1. | Engine Oil Jet |

|

|

|

| 2. | Piston/Connecting Rod Assembly |

|

|

|

|

|

|

| 3. | Crankshaft |

|

|

|

||||||

|

|

|

| 4. | Main Bearing Clearance Inspection |

|

|

|

||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||

| 5. | Crankshaft Main Bearing - Selection |

|

|

|

|

|

|

|

|

|

|||||||||||||||||

| 6. | Cylinder Lower Block Assembly |

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

| 7. | Connecting Rod Bearing Clearance Inspection |

|

|

|

|||||||||||||||||||||||||||||||||||||||||||

| 8. | Connecting Rod Bearing Selection |

|

1. |

Inspect each connecting rod for cracks and heat damage. |

redandrunisind

redandrunisind

|

2. |

Each connecting rod has a tolerance range from 0 to 0.024 mm (0.00094 in), in 0.006 mm (0.00024 in) increments, depending on the size of its big end bore. It's then stamped with a number or bar (1, 2, 3, or 4/l, ll, lll, or llll) indicating the range. You may find any combination of numbers and bars in any engine. (Half the number or bar is stamped on the rod cap, the other half is on the connecting rod.) If you cannot read the code because of an accumulation of oil and varnish, do not scrub it with a wire brush or scraper. Clean it only with solvent or detergent. |

|||||

|

||||||

|

|

|

|

|

|

|||||||||||||||||

| 9. | Connecting Rod Cap and The Bearing Half |

|

|

|

|

|

|

|||||||||

| 10. | Engine Baffle Plate |

|

|

|

| 11. | Engine Oil Strainer |

|

|

|

| 12. | Oil Pan Assembly |

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|||||||||||||||||

| 13. | Cylinder Head Assembly |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

| 14. | Set The No.1 Piston at Top Dead Center (Without Cam Chain Case/Oil Pump) |

|

|

|

| 15. | Cam Chain |

|

|

|

|

|

|

|

|

|

| 16. | Cam Chain Auto-Tensioner |

|

|

|

||||||

|

|

|

|

|

|

| 17. | Engine Oil Pump Assembly |

|

|

|

||||||||||||||||||||||||||

|

|

|

||||||||||||||

|

|

|

||||||||||||||||||||||||||||||

| 18. | Crankshaft Oil Seal, Transmission side |

|

|

|

|

|

|

||||||||||

| 19. | Crankshaft Pulley |

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

||||||||||

| 20. | Valve Clearance Adjustment |

|

|

|

|

2. |

Select the correct feeler gauge for the valve clearance you are going to check. |

|||||||||

|

||||||||||

no!

no!

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

| 21. | Cylinder Head Cover and/or Packing |

|

|

|

|||||||||||||||

|

|

|

||||||||||||||||||||

|

|

|

||||||||||||||||||||

|

|

|

| 22. | Auto Tensioner Assembly |

|

|

|

| 23. | Water Pump Pulley |

|

|

|

| 24. | A/C Compressor Bracket |

|

|

|

| 25. | Intermediate Shaft Assembly |

|

|

|

||||||

|

|

|

| 26. | Lower Torque Rod Bracket (A/T) |

|

|

|

| 27. | Alternator |

|

|

|

| 28. | Thermostat Housing (Natural Gas Model) |

|

|

|

| 29. | Catalytic Converter (Natural Gas Model) |

|

|

|

| 30. | Exhaust Chamber Cover (Natural Gas Model) |

|

|

|

| 31. | A/F Sensor (Sensor 1) |

|

|

|

| 32. | Drive Plate Assembly |

|

|

|

| 33. | Automatic Transmission Assembly (A/T) |

|

|

|

| 34. | Engine Wire Harness |

|

|

|

| 35. | Intake Manifold and Throttle Body Assembly (Natural Gas Model) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Block and Piston Inspection (R18Z1)

Block and Piston Inspection (R18Z1)

Removal

1.

Intake Manifold and Throttle Body Assembly

1.

Remove the intake air duct.

...

Cylinder Bore Honing (R18Z1)

Cylinder Bore Honing (R18Z1)

Removal

1.

Intake Manifold and Throttle Body Assembly

1.

Remove the intake air duct.

...

See also:

Honda Civic Owners Manual. Advanced Airbags

The airbags have advanced features to help reduce the likelihood of airbag

related

injuries to smaller occupants.

The driver’s advanced airbag system includes a

seat position sensor.

Based on information from this sensor and the

severity of the impact, the advanced airbag

system dete ...

[av

[av

u.75mm

u.75mm

na.nono

na.nono nojournal

nojournal bunamvllluwgemam,inwmam;

bunamvllluwgemam,inwmam;

(pulley

(pulley a.ndendam,amznvllred/pink/pinkvellawpink/emwnbrawnsmnllevmd

a.ndendam,amznvllred/pink/pinkvellawpink/emwnbrawnsmnllevmd

mm

mm

inmmam

inmmam

secounstep

secounstep

...,is(1.2

...,is(1.2

nokvf-in.

nokvf-in.

25mm(7(32k1n1omm12

25mm(7(32k1n1omm12

o7jaanmo2oa

o7jaanmo2oa

inl.25mmssn-m

inl.25mmssn-m

inmmn-mu.o

inmmn-mu.o mms.

mms. u.z5mm75n-mmm

u.z5mm75n-mmm

imm

imm :1mm.....

:1mm.....

55

55 usmmn-mlbml)

usmmn-mlbml)