Honda Civic Service Manual: Block and Piston Inspection (R18Z1)

Removal

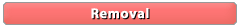

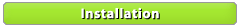

| 1. | Intake Manifold and Throttle Body Assembly |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2. | Engine Wire Harness |

|

|

|

| 3. | Manual Transmission Assembly (M/T) |

|

|

|

| 4. | Pressure Plate |

|

|

|

| 5. | Clutch Disc |

|

|

|

| 6. | Flywheel |

|

|

|

|||||||||

| 7. | Automatic Transmission Assembly (A/T) |

|

|

|

| 8. | Drive Plate Assembly |

|

|

|

| 9. | A/F Sensor (Sensor 1) |

|

|

|

| 10. | Exhaust Chamber Cover |

|

|

|

| 11. | Catalytic Converter and EGR Pipe Assembly |

|

|

|

|

|

|

| 12. | Thermostat Housing |

|

|

|

| 13. | Alternator |

|

|

|

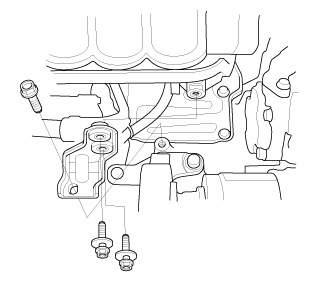

| 14. | Lower Torque Rod Bracket (M/T) |

|

|

|

| 15. | Lower Torque Rod Bracket (A/T) |

|

|

|

| 16. | Intermediate Shaft Assembly |

|

|

|

|

|

|

||||||

| 17. | A/C Compressor Bracket |

|

|

|

| 18. | Water Pump Pulley |

|

|

|

| 19. | Auto Tensioner Assembly |

|

|

|

| 20. | Cylinder Head Cover and/or Packing |

|

|

|

|

|

|

| 21. | Check The No.1 Piston at Top Dead Center (With Cam Chain Case/Oil Pump) |

|

|

|

| 22. | Crankshaft Pulley |

|

|

|

| 23. | Engine Oil Pump Assembly |

|

|

|

|

|

|

| 24. | Cam Chain Auto-Tensioner |

|

|

|

||||||||||||

|

|

|

|

|

|

||||||||||||

|

|

|

| 25. | Cam Chain |

|

|

|

| 26. | Cylinder Head Assembly |

|

|

|

| 27. | Oil Pan Assembly |

|

|

|

|

|

|

| 28. | Engine Oil Strainer |

|

|

|

| 29. | Engine Baffle Plate |

|

|

|

| 30. | Connecting Rod Cap and The Bearing Half |

|

|

|

| 31. | Cylinder Lower Block Assembly |

|

|

|

|

|

|

|

|

|

|

|

|

| 32. | Crankshaft |

|

|

|

| 33. | Crankshaft Oil Seal, Transmission Side |

|

|

|

| 34. | Piston/Connecting Rod Assembly |

|

|

|

|

|

|

||||||||||||

Inspection

Inspection

| 1. | Block and Piston - Inspection |

|

1. |

Check the pistons for distortion or cracks. Check the pistons for distortion

or cracks. |

|||||||||||||

|

||||||||||||||

|

2. |

Measure the piston skirt diameter at a point 14 mm (0.55 in) from the bottom of the skirt. |

| 2. | Cylinder Block - Inspection |

|

1. |

Measure the wear and taper Y at three levels inside each cylinder as shown. If measurements in any cylinder are beyond the oversize bore service limit, replace the engine block. |

|||||||||||||||||||

|

||||||||||||||||||||

torun:in)m-um-in-nlsommsecond(1measurementmmmmmeasurement

torun:in)m-um-in-nlsommsecond(1measurementmmmmmeasurement

|

2. |

Hone any cored or scratched cylinder bores if needed. |

|

3. |

Check the top of the engine block for warpage. Measure along the edges and across the center as shown. |

|||||||

|

||||||||

|

4. |

Calculate the difference between the cylinder bore diameter and the piston diameter. If the clearance is near, or exceeds the service limit, inspect the piston and the cylinder bore for excessive wear. |

|||||||||

|

||||||||||

servicelimiyo.osmm

servicelimiyo.osmm

Installation

| 1. | Piston/Connecting Rod Assembly |

|

|

|

|

|

|

| 2. | Crankshaft |

|

|

|

||||||

|

|

|

| 3. | Main Bearing Clearance Inspection |

|

|

|

||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||

| 4. | Crankshaft Main Bearing - Selection |

|

|

|

|

|

|

|

|

|

|||||||||||||||||

| 5. | Cylinder Lower Block Assembly |

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||

| 6. | Connecting Rod Bearing Clearance Inspection |

|

|

|

|||||||||||||||||||||||||||||||||||||||||||

| 7. | Connecting Rod Bearing Selection |

|

1. |

Inspect each connecting rod for cracks and heat damage. |

redandrunisind

redandrunisind

|

2. |

Each connecting rod has a tolerance range from 0 to 0.024 mm (0.00094 in), in 0.006 mm (0.00024 in) increments, depending on the size of its big end bore. It's then stamped with a number or bar (1, 2, 3, or 4/l, ll, lll, or llll) indicating the range. You may find any combination of numbers and bars in any engine. (Half the number or bar is stamped on the rod cap, the other half is on the connecting rod.) If you cannot read the code because of an accumulation of oil and varnish, do not scrub it with a wire brush or scraper. Clean it only with solvent or detergent. |

|||||

|

||||||

|

|

|

|

|

|

|||||||||||||||||

| 8. | Connecting Rod Cap and The Bearing Half |

|

|

|

|

|

|

|||||||||

| 9. | Engine Baffle Plate |

|

|

|

| 10. | Engine Oil Strainer |

|

|

|

| 11. | Oil Pan Assembly |

|

|

|

|||||||||||||||||||||||

|

|

|

|

|

|

|||||||||||||||||

| 12. | Cylinder Head Assembly |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

| 13. | Set The No.1 Piston at Top Dead Center (Without Cam Chain Case/Oil Pump) |

|

|

|

| 14. | Cam Chain |

|

|

|

|

|

|

|

|

|

| 15. | Cam Chain Auto-Tensioner |

|

|

|

||||||

|

|

|

|

|

|

| 16. | Engine Oil Pump Assembly |

|

|

|

||||||||||||||||||||||||||

|

|

|

||||||||||||||

|

|

|

||||||||||||||||||||||||||||||

| 17. | Crankshaft Oil Seal, Transmission side |

|

|

|

|

|

|

||||||||||

| 18. | Crankshaft Pulley |

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

||||||||||

| 19. | Valve Clearance Adjustment |

|

|

|

|

2. |

Select the correct feeler gauge for the valve clearance you are going to check. |

|||||||||

|

||||||||||

no!

no!

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

| 20. | Cylinder Head Cover and/or Packing |

|

|

|

|||||||||||||||

|

|

|

||||||||||||||||||||

|

|

|

||||||||||||||||||||

|

|

|

| 21. | Auto Tensioner Assembly |

|

|

|

| 22. | Water Pump Pulley |

|

|

|

| 23. | A/C Compressor Bracket |

|

|

|

| 24. | Intermediate Shaft Assembly |

|

|

|

||||||

|

|

|

| 25. | Lower Torque Rod Bracket (M/T) |

|

|

|

| 26. | Lower Torque Rod Bracket (A/T) |

|

|

|

| 27. | Alternator |

|

|

|

| 28. | Thermostat Housing |

|

|

|

| 29. | Catalytic Converter and EGR Pipe Assembly |

|

|

|

|

|

|

| 30. | Exhaust Chamber Cover |

|

|

|

| 31. | A/F Sensor (Sensor 1) |

|

|

|

| 32. | Drive Plate Assembly |

|

|

|

| 33. | Automatic Transmission Assembly (A/T) |

|

|

|

| 34. | Flywheel |

|

|

|

|

|

|

| 35. | Clutch Disc |

|

|

|

||||||||||||

| 36. | Pressure Plate |

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||

| 37. | Manual Transmission Assembly (M/T) |

|

|

|

| 38. | Engine Wire Harness |

|

|

|

| 39. | Intake Manifold and Throttle Body Assembly |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Block and Piston Inspection (R18A9)

Block and Piston Inspection (R18A9)

Removal

1.

Intake Manifold and Throttle Body Assembly (Natural Gas Model)

1.

Remove the intake air duct.

...

Cylinder Bore Honing (R18A9)

Cylinder Bore Honing (R18A9)

Removal

1.

Intake Manifold and Throttle Body Assembly (Natural Gas Model)

1.

Remove the intake air duct.

...

See also:

Honda Civic Owners Manual. Getting Ready to Replace the Flat Tire

Open the trunk floor lid.

Take the tool case out of the trunk. Take

the jack and wheel nut wrench out of the

tool case.

Unscrew the wing bolt, and remove the

spacer cone. Then, remove the spare tire.

Place a wheel block or rock in front and rear

of the whee ...

n7lab-wnolun

n7lab-wnolun

[av

[av

na.nono

na.nono nojournal

nojournal bunamvllluwgemam,inwmam;

bunamvllluwgemam,inwmam;

(pulley

(pulley a.ndendam,amznvllred/pink/pinkvellawpink/emwnbrawnsmnllevmd

a.ndendam,amznvllred/pink/pinkvellawpink/emwnbrawnsmnllevmd

mm

mm

inmmam

inmmam

secounstep

secounstep

...,is(1.2

...,is(1.2

nokvf-in.

nokvf-in.

25mm(7(32k1n1omm12

25mm(7(32k1n1omm12

o7jaanmo2oa

o7jaanmo2oa

inl.25mmssn-m

inl.25mmssn-m

inmmn-mu.o

inmmn-mu.o mms.

mms. mm

mm u.z5mm75n-mmm

u.z5mm75n-mmm

11

11 num(2.2m.2:m41!

num(2.2m.2:m41! 22n-m

22n-m

55

55 usmmn-mlbml)

usmmn-mlbml)

:2minn-inno

:2minn-inno (pm

(pm

a7aag-suaa1aa

a7aag-suaa1aa