Honda Civic Service Manual: Valve Guide Replacement (R18A9)

| 1. | Fuel Pressure - Relieving (Between the engine and the manual shut-off valve) (Natural Gas Model) |

|

|

Compressed natural gas is flammable and highly explosive. You could be

killed or seriously injured if leaking natural gas is ignited.

|

| 2. | Vehicle Lift |

|

| 3. | Tire and Wheel-Removal, Front Right |

|

|

|

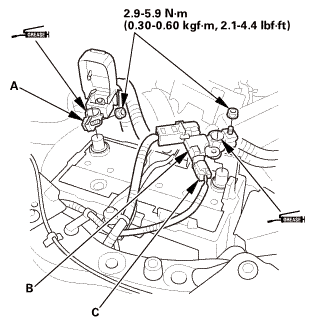

| 4. | Battery Terminal - Disconnection |

|

|

|

|||||||||||||||||||||||||||

| 5. | Battery |

|

|

|

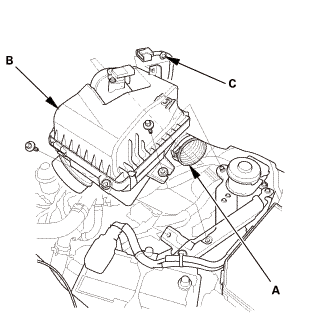

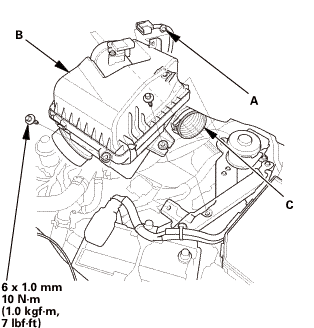

| 6. | Engine Cover |

|

|

|

| 7. | Radiator Cap |

|

| 8. | Radiator Coolant - Replacement |

|

|

|

| 9. | Intake Air Pipe |

|

|

|

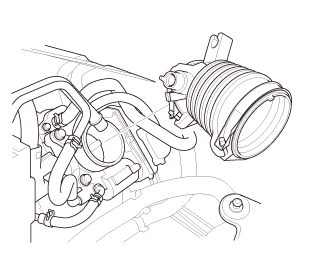

| 10. | Air Cleaner |

|

|

|

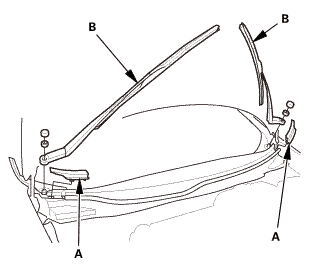

| 11. | Wiper Arm Assembly |

|

|

|

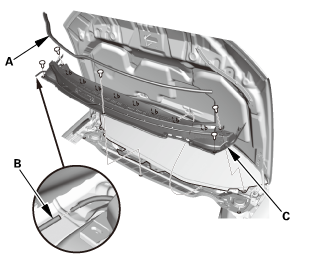

| 12. | Both Side Cowl Covers |

|

|

|

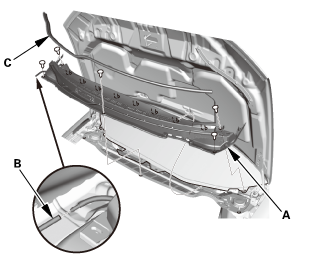

| 13. | Center Cowl Cover |

|

|

|

| 14. | Under Cowl Panel |

|

|

|

| 15. | Fuel Feed Hose (Natural Gas Model) |

|

|

|

| 16. | Intake Air Duct |

|

|

|

| 17. | Throttle Body - Remove (Natural Gas Model) |

|

|

|

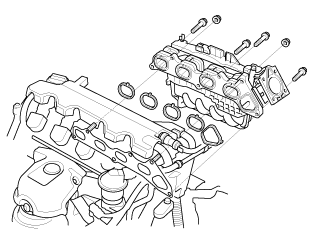

| 18. | Intake Manifold Assembly (Natural Gas Model) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 19. | Cylinder Head Peripheral Assembly |

|

|

|

|

|

|

|

|

|

|

|

|

| 20. | Ignition Coil |

|

|

|

| 21. | A/F Sensor (Sensor 1) |

|

|

|

| 22. | Exhaust Chamber Cover (Natural Gas Model) |

|

|

|

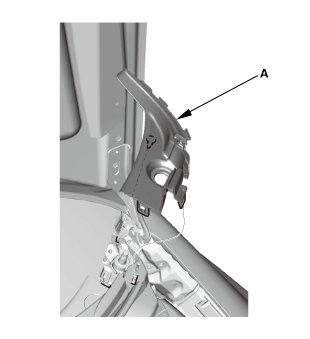

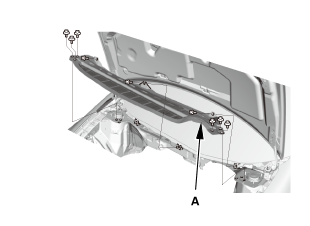

| 23. | Splash Shield |

|

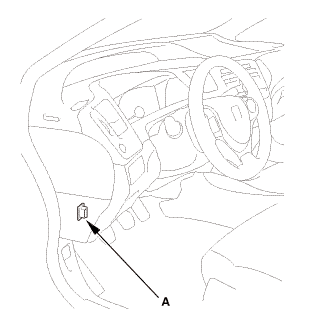

1. |

Remove the splash shield (A). |

| 24. | Engine Undercover |

|

|

|

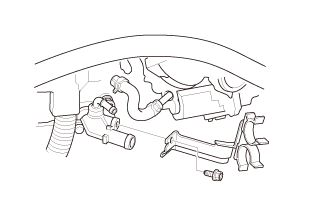

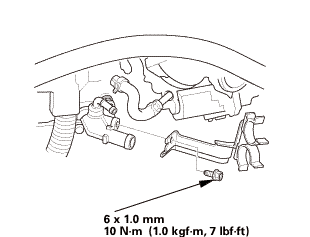

| 25. | Secondary HO2S |

|

|

|

| 26. | Exhaust Pipe A (Except CVT) |

|

|

|

| 27. | Catalytic Converter (Natural Gas Model) |

|

|

|

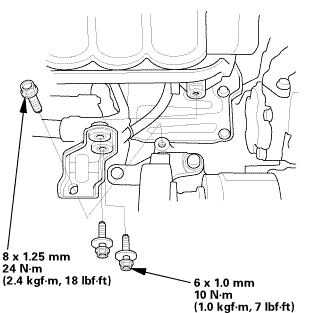

| 28. | Thermostat Housing Peripheral Assembly (Natural Gas Model) |

|

|

|

|

|

|

|

|

|

| 29. | Thermostat Housing (Natural Gas Model) |

|

|

|

| 30. | Water Pump Pulley Mounting Bolt - Loosen |

|

|

|

| 31. | Drive Belt |

|

|

|

| 32. | Alternator |

|

|

|

|

|

|

| 33. | Water Pump Pulley |

|

|

|

| 34. | Auto Tensioner Assembly |

|

|

|

| 35. | Cylinder Head Cover and/or Packing |

|

|

|

|

|

|

| 36. | Check The No.1 Piston at Top Dead Center (With Cam Chain Case/Oil Pump) |

|

|

|

| 37. | Crankshaft Pulley |

|

|

|

| 38. | Engine Jack Support (State Of A Low Vehicle) |

|

| 39. | Mounting Bracket, Engine Side |

|

|

|

| 40. | Engine Oil Pump Assembly |

|

|

|

|

|

|

| 41. | Cam Chain Auto-Tensioner |

|

|

|

||||||||||||

|

|

|

|

|

|

||||||||||||

|

|

|

| 42. | Cam Chain |

|

|

|

| 43. | Cylinder Head Assembly |

|

|

|

| 44. | Rocker Arm Assembly |

|

|

|

|

|

|

|

|

|

| 45. | Camshaft Sprocket |

|

|

|

| 46. | Camshaft |

|

|

|

| 47. | Valve Spring |

|

|

|

|

|

|

| 48. | Valve Seal |

|

|

|

|

|

|

| 49. | Valve Guide |

|

|

|

|

|

|

|

|

|

||||||||||||

| 1. | Valve Guide |

|

|

|

||||||||||||||||

|

|

|

| 2. | Valve Seal |

|

|

|

||||||

| 3. | Valve Spring |

|

|

|

|

|

|

||||||

| 4. | Camshaft |

|

|

|

| 5. | Camshaft Sprocket |

|

|

|

||||||||||||||||||||||

| 6. | Rocker Arm Assembly |

|

|

|

|||||||||||||||

|

|

|

|

|

|

||||||||||

| 7. | Cylinder Head Assembly |

|

|

|

|

|

|

|

|

|

|

|

|

||||||

| 8. | Cam Chain |

|

|

|

|

|

|

|

|

|

| 9. | Cam Chain Auto-Tensioner |

|

|

|

||||||

|

|

|

|

|

|

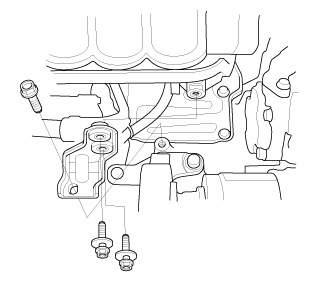

| 10. | Engine Oil Pump Assembly |

|

|

|

||||||||||||||||||||||||||

|

|

|

||||||||||||||

|

|

|

||||||||||||||||||||||||||||||

| 11. | Mounting Bracket, Engine Side |

|

|

|

| 12. | Engine Jack Support (State Of A Low Vehicle) |

|

| 13. | Transmission Mount Bracket Mounting Bolt - Loosen |

|

M/T

A/T

|

|

| 14. | Lower Torque Rod - Loosen |

|

|

|

| 15. | Side Engine Mount - Tighten |

|

|

|

| 16. | Transmission Mount Bracket Mounting Bolt - Tighten |

|

1. |

Tighten the transmission mount bracket mounting bolt and nuts. |

M/T

i2mm

i2mm

A/T

nz

nz

| 17. | Lower Torque Rod Mounting Bolt - Tighten |

|

|

|

| 18. | Crankshaft Pulley |

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

||||||||||

| 19. | Valve Clearance Adjustment |

|

|

|

|

2. |

Select the correct feeler gauge for the valve clearance you are going to check. |

|||||||||

|

||||||||||

no!

no!

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

| 20. | Cylinder Head Cover and/or Packing |

|

|

|

|||||||||||||||

|

|

|

||||||||||||||||||||

|

|

|

||||||||||||||||||||

|

|

|

| 21. | Auto Tensioner Assembly |

|

|

|

| 22. | Water Pump Pulley |

|

|

|

| 23. | Alternator |

|

|

|

|

|

|

| 24. | Drive Belt |

|

|

|

| 25. | Water Pump Pulley Mounting Bolt - Tighten |

|

|

|

| 26. | Thermostat Housing (Natural Gas Model) |

|

|

|

| 27. | Thermostat Housing Peripheral Assembly (Natural Gas Model) |

|

|

|

|

|

|

|

|

|

| 28. | Catalytic Converter (Natural Gas Model) |

|

|

|

| 29. | Exhaust Pipe A (Except CVT) |

|

|

|

| 30. | Secondary HO2S |

|

|

|

| 31. | Engine Undercover |

|

|

|

| 32. | Splash Shield |

|

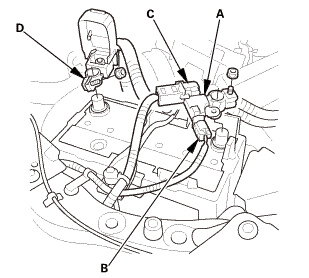

1. |

Install the splash shield (A). |

| 33. | Exhaust Chamber Cover (Natural Gas Model) |

|

|

|

| 34. | A/F Sensor (Sensor 1) |

|

|

|

| 35. | Ignition Coil |

|

|

|

| 36. | Cylinder Head Peripheral Assembly |

|

|

|

|

|

|

|

|

|

|

|

|

| 37. | Intake Manifold Assembly (Natural Gas Model) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 38. | Throttle Body - Install (Natural Gas Model) |

|

|

|

| 39. | Intake Air Duct |

|

|

|

| 40. | Fuel Feed Hose (Natural Gas Model) |

|

|

|

| 41. | Under Cowl Panel |

|

|

|

| 42. | Center Cowl Cover |

|

|

|

| 43. | Both Side Cowl Covers |

|

|

|

| 44. | Wiper Arm Assembly |

|

|

|

| 45. | Air Cleaner |

|

|

|

| 46. | Intake Air Pipe |

|

|

|

| 47. | Engine Cover |

|

|

|

| 48. | Battery |

|

|

|

||||||

| 49. | Battery Terminal - Reconnection |

|

|

|

|||||||||||||||||||

| 50. | Manual Shut-off Valve - Open (Natural Gas Model) |

|

|

|

| 51. | Fuel Supply System Leak - Inspection (Natural Gas Model) |

|

|

|

|

|

|

|

|

|

| 52. | Radiator Coolant - Replacement (Natural Gas Model) |

|

1. |

Follow the chart and pour coolant into the radiator up to the base of the filler neck. |

|||||||||||||||||||||||||||||||||||||

|

NOTE: |

||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||

|

*: When you want to winterize the coolant with the minimum amount of coolant change but the current coolant concentration in the vehicle is unknown, you must drain all coolant from the cooling system. |

||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||

| 53. | Tire and Wheel-Installation, Front Right |

|

|

|

||||||

| 54. | Warm Up The Engine |

|

| 55. | HDS DLC - Connection |

|

|

|

| 56. | Idle Speed - Inspection (Natural Gas Model) |

|

||||||||||||||||||||||||||||||||||||||||||||||

| 57. | CKP Pattern Clear/CKP Pattern Learn |

|

| 58. | Ignition Timing - Inspection |

|

|

|

|

|

|

||||||||||||||||

| 59. | Maintenance Minder Reset |

|

Valvetrain

Valvetrain

...

Valve Guide Replacement (R18Z1)

Valve Guide Replacement (R18Z1)

1.

Vehicle Lift

1.

Raise the vehicle on a lift, and make sure it is securely supported.

2. ...

See also:

Honda Civic Service Manual. Moonroof Frame/Drain Channel Slider and Cable Assembly Removal and Installation

(2-door)

Removal

1.

Battery Terminal (SRS) - Disconnection

1.

Make sure the ignition switch is in LOCK (0).

2.

Disconnect and isolate the negative cab ...

12x1mm

12x1mm

[av

[av

o77s7n

o77s7n

mmmmmlmmam

mmmmmlmmam

tommnomm

tommnomm

inmmam

inmmam

secounstep

secounstep

...,is(1.2

...,is(1.2

nokvf-in.

nokvf-in.

25mm(7(32k1n1omm12

25mm(7(32k1n1omm12

125mmnminm.:125mm

125mmnminm.:125mm

nxl.mm

nxl.mm

o7jaanmo2oa

o7jaanmo2oa

inl.25mmssn-m

inl.25mmssn-m mmn-m(2

mmn-m(2 i.nmm(n.i

i.nmm(n.i

imm

imm

:1mm.....

:1mm..... inmm125mm22i21

inmm125mm22i21

mm

mm

mmm.uimm

mmm.uimm

22mm)2222

22mm)2222

1.122

1.122

mminmuan

mminmuan