Honda Civic Service Manual: A/T Mainshaft Disassembly, Reassembly, and Inspection (A/T)

View

View

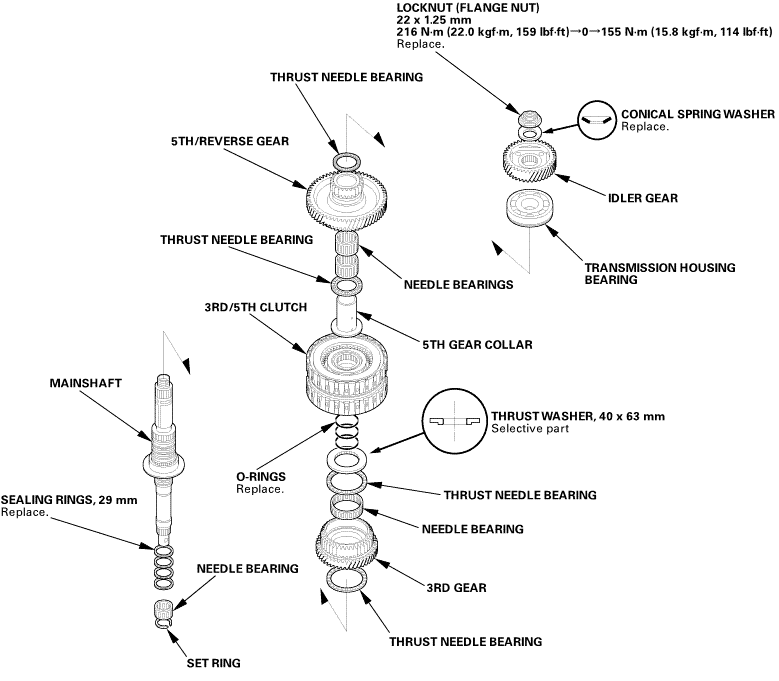

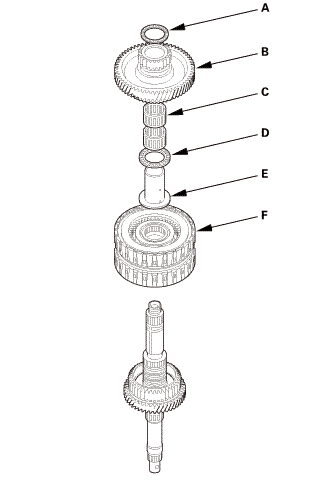

| 1. | A/T Mainshaft Exploded View |

|

Exploded View |

mun......usuzzmzev.sunmmsmlssloummsmasmgearmmmmamthrust

mun......usuzzmzev.sunmmsmlssloummsmasmgearmmmmamthrust

Disassembly

Disassembly

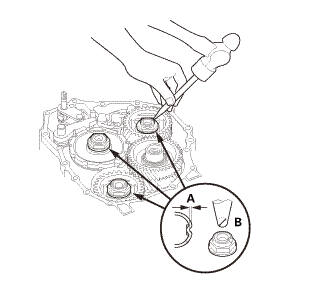

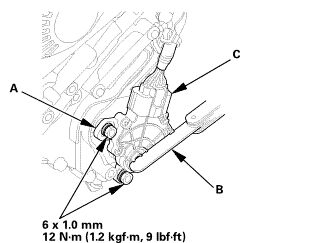

| 1. | Transmission Range Switch Cover |

|

|

|

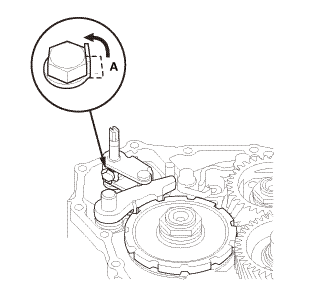

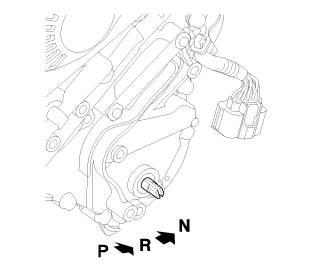

| 2. | Transmission Range Switch |

|

|

|

| 3. | Transmission Range Switch Subharness |

|

|

|

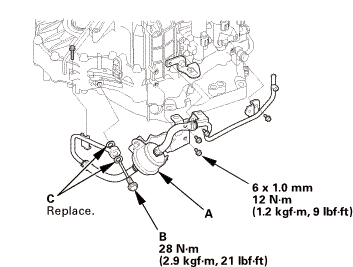

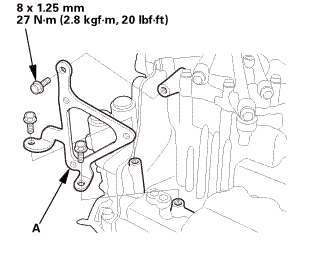

| 4. | ATF Warmer Bracket |

|

|

|

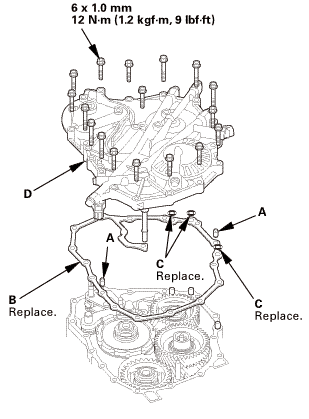

| 5. | Transmission End Cover |

|

|

|

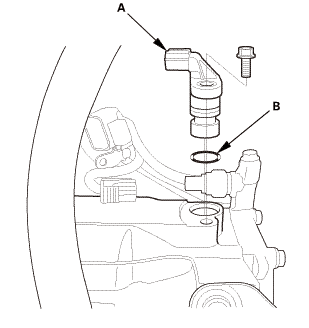

| 6. | Input Shaft (Mainshaft) Speed Sensor |

|

|

|

| 7. | Output Shaft (Countershaft) Speed Sensor |

|

|

|

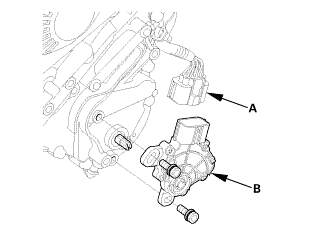

| 8. | A/T Clutch Pressure Control Solenoid Valve A |

|

|

|

| 9. | A/T Clutch Pressure Control Solenoid Valve B and C |

|

|

|

| 10. | ATF Filter Assembly |

|

|

|

| 11. | A/T Solenoid Cover |

|

|

|

| 12. | A/T Shift Solenoid Wire Harness - Disconnection |

|

|

|

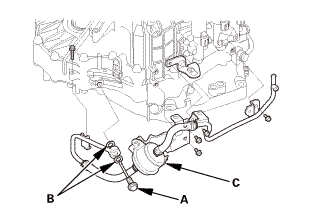

| 13. | ATF Pipe |

|

|

|

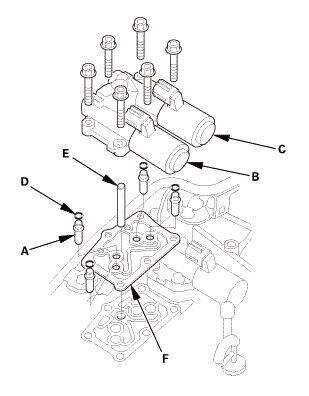

| 14. | End Cover Idler Gear Assembly |

|

|

|

|

|

|

||||||

|

|

|

||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

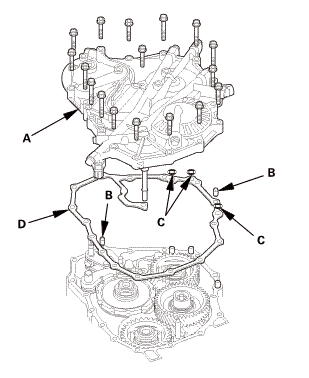

| 15. | A/T Transmission Housing |

|

|

|

||||||||||||||||||

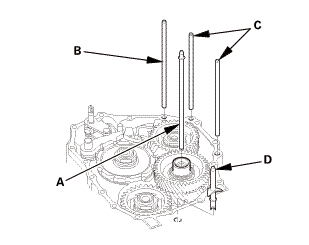

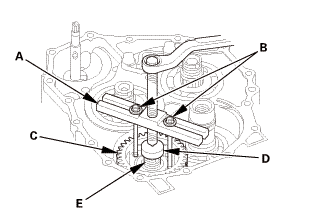

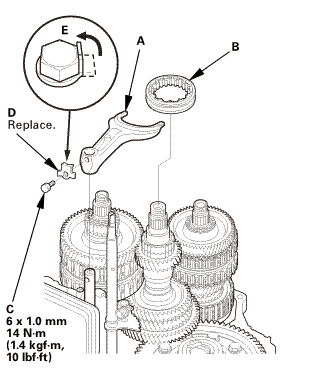

| 16. | A/T Reverse Idler Gear |

|

|

|

|

|

|

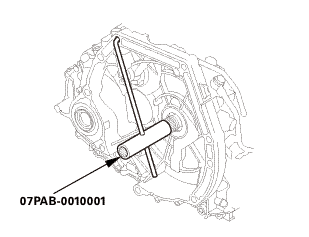

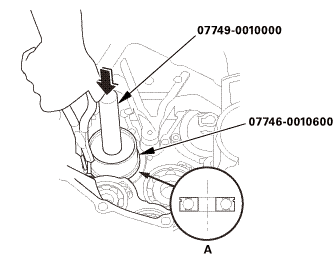

| 17. | A/T Mainshaft Bearing |

|

|

|

|||||||||

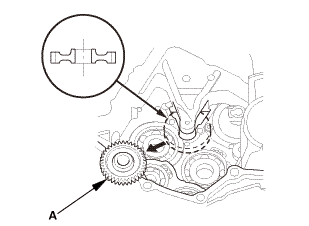

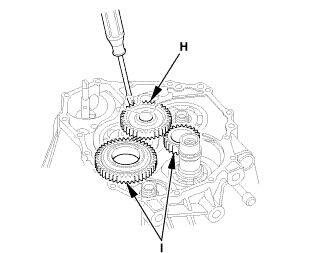

| 18. | A/T Countershaft Reverse Gear |

|

|

|

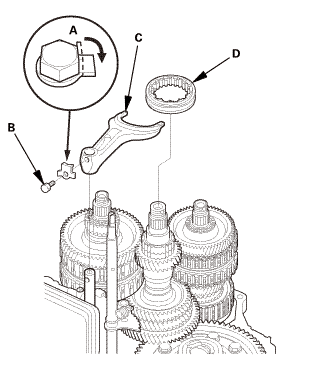

| 19. | Shift fork Shaft |

|

|

|

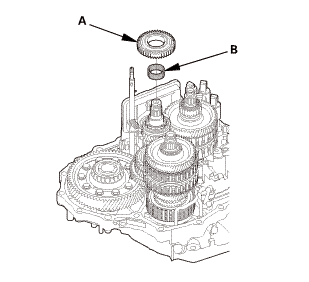

| 20. | A/T Mainshaft and Countershaft and Secondary Shaft Assembly |

|

|

|

| 21. | A/T Mainshaft |

|

|

|

|

|

|

|

|

|

Inspection

Inspection

| 1. | Mainshaft - Inspection |

|

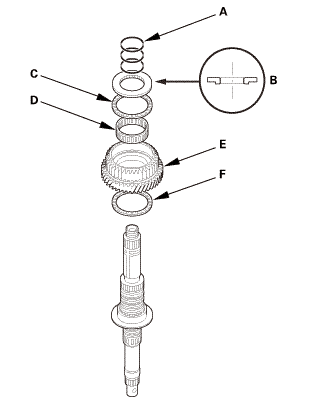

| 2. | 3rd Gear Axial Clearance - Inspection |

|

|

|

|||||||||

|

|

|

|

|

|

|||||||||

|

|

|

Reassembly

Reassembly

|

NOTE: Apply a light coat of clean ATF on all moving parts before reassembly. |

| 1. | A/T Mainshaft |

|

|

|

|

|

|

|

|

|

| 2. | A/T Mainshaft and Countershaft and Secondary Shaft Assembly |

|

|

|

| 3. | Shift fork Shaft |

|

|

|

| 4. | A/T Countershaft Reverse Gear |

|

|

|

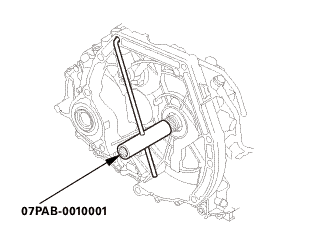

| 5. | A/T Mainshaft Bearing |

|

|

|

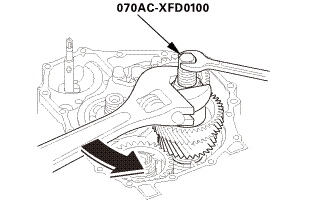

| 6. | A/T Reverse Idler Gear |

|

|

|

|

|

|

|

|

|

| 7. | A/T Transmission Housing |

|

|

|

||||||||||||||||||||||||

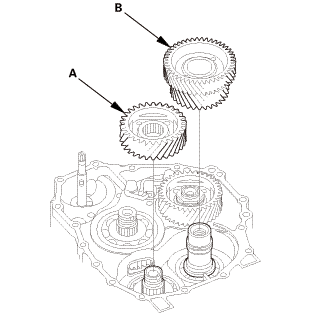

| 8. | End Cover Idler Gear Assembly |

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||

|

|

|

||||||||||||||||||||||||||||||

|

|

|

|||||||||

|

|

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|||||||||

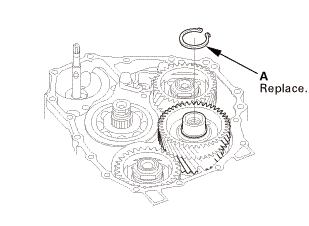

|

29. |

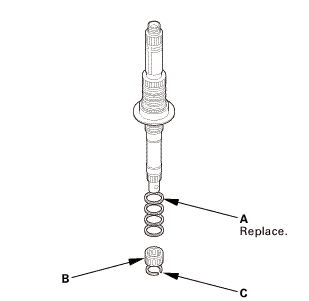

If the measurement is out of the standard, select and install the appropriate park lever stop (A) from the table. |

|

PARK LEVER STOP

|

|

30. |

After replacing the park lever stop, make sure the distance is within the tolerance. |

|

|

|

| 9. | ATF Pipe |

|

|

|

| 10. | A/T Shift Solenoid Wire Harness - Reconnection |

|

|

|

||||||||||||||||||||||

| 11. | A/T Solenoid Cover |

|

|

|

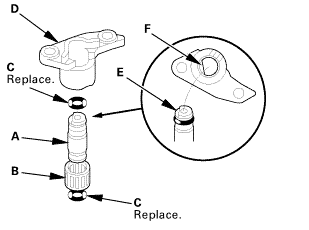

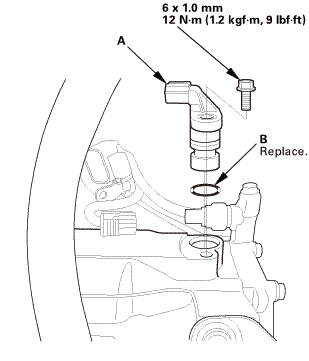

| 12. | ATF Filter Assembly |

|

1. |

Install the ATF inlet line/ATF hose/ATF filter assembly (A). |

himm12mm

himm12mm

|

2. |

Install the banjo bolt (B) using new sealing washers (C). |

| 13. | A/T Clutch Pressure Control Solenoid Valve B and C |

|

|

|

| 14. | A/T Clutch Pressure Control Solenoid Valve A |

|

|

|

| 15. | Output Shaft (Countershaft) Speed Sensor (A/T) |

|

|

|

| 16. | Input Shaft (Mainshaft) Speed Sensor |

|

|

|

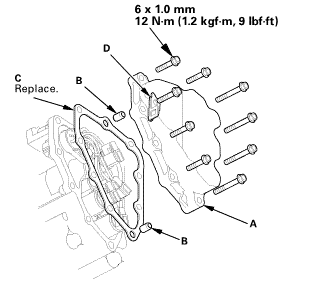

| 17. | Transmission End Cover |

|

|

|

| 18. | ATF Warmer Bracket |

|

|

|

| 19. | Transmission Range Switch Subharness |

|

|

|

| 20. | Transmission Range Switch |

|

|

|

||||||

|

|

|

||||||

|

|

|

|

|

|

||||||||||||

| 21. | Transmission Range Switch Cover |

|

|

|

A/T Housing Countershaft Bearing Replacement (A/T)

A/T Housing Countershaft Bearing Replacement (A/T)

Removal

1.

Transmission Range Switch Cover

1.

Remove the transmission range switch cover (A).

...

ATF Temperature Sensor Removal and Installation (A/T)

ATF Temperature Sensor Removal and Installation (A/T)

7371J4

1.

Vehicle Lift

1.

Raise the vehicle on a lift, and make sure it is securely supported.

...

See also:

Honda Civic Service Manual. High Mount Brake Light Removal and Installation - Without Trunk Lid

Spoiler (4-door except Natural Gas models)

Removal

SRS components are located in this area. Review the SRS component

locations and the precautions and procedures before doing repairs

or service.

1.

Rear Seat Cushion

...

22mmimm

22mmimm

mm21inmk)

mm21inmk) 1a1.2:mmmn!(4.:

1a1.2:mmmn!(4.:

o7aacxfnmoa

o7aacxfnmoa

lve.l(camwur,

lve.l(camwur, inmm

inmm

mmi11

mmi11

mm12u....um,!mk)

mm12u....um,!mk) mm27lhf!

mm27lhf!

mmnm

mmnm